- kingda XPS - flame retardant board

- kingda xps - The common blue, red, yellow

- kingda xps - Roof extrusion board

- kingda xps - Internal and external wall extrusion

- kingda xps - Cold storage and purification worksho

- kingda xps - Floor heating extrusion board

- kingda xps- Steel structure layer and sandwich ext

- kingda xps - Special shape sheet extrusion board

- Promotion Keywords

Dongguan city, kingda plastic insulation board co., LTD

Contact: manager zhao

Mobile phone: 13509011897

The phone: 0769-88127882

Fax:0769-88128231

Email:2875488916@qq.com

Web site:www.dgkingda.com

Address:Zhongtang town Zhancui Nan di Industrial area

-

First, the choice of materials:

The basic properties of materials must be small density, high compressive strength, low water absorption, convenient paving, easy to control, paving density, etc., and considering the technical requirements of layered laying. Higher quality requirements for materials.

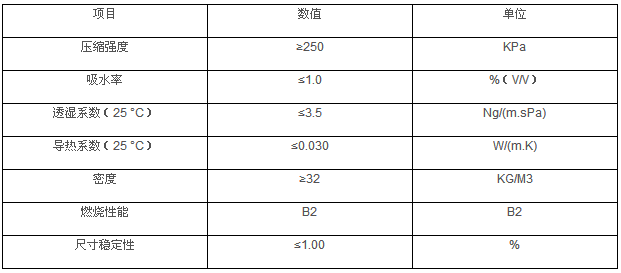

The performance index of two, dligence plastic extruded board.

We have high compressive strength concrete extruded plate (maximum bearing strength can reach 50 tons per square meter), low water absorption (closed structure materials, theory of water absorption rate is zero), long service life of the material (to keep the main performance index of 50 years rate of 70% or more) and other characteristics, is suitable for the greening of backfill earthwork construction replacement project in. It has been widely used in Shanghai Nanjing high speed railway, Qinghai Tibet railway and Expo project.

The main performance indexes are as follows

Three, construction notes:

1, the selection of materials must comply with national standards, to meet the bulk density, compression, water absorption and other important technical indicators.

2, such as lightweight materials replacement earthwork below the ground water level, the need to consider anti floating weight requirements.

3, to ensure that lightweight materials change fill thickness, to achieve the best economic benefits. Also ensure that the upper earth molding thickness. Ensure plants growing demand. General value of soil layer is not less than 2 meters.

4, pay attention to replacement soil high-level control, timber connections, laying arrangements, etc..

5 、 the Extrusion board can be cut according to the construction needs, but the area after cutting may not be less than 0.3 square meters. Unilateral length is not less than 0.5 meters.

6, in order to ensure the stability of the shape, between the plates should be staggered stacking.

Four 、 construction technological process:

1, according to the type of reactor height, height of earth excavation replacement XPS board support. Make sure the earth is excavated.

2, before the Extrusion board laying, first of all, the construction of concrete cushion, 100mm thick C20 concrete. The bottom crushed stone cushion 100mm is taken as a water filtration measure. When the cushion is poured and rammed, the 10m sub gap joint is kept in the vicinity of each subarea, the change of the elevation is obvious, and the inner part of the large area cushion is arranged. Ensure that the overall XPS is placed inside the drain after use.

3, according to regional trends to develop control axis.

4, along the axial direction of layer laying Midas XPS board. (laying down the shape according to the design of the construction)

5. After laying, it can be covered directly on the board. Can be covered with a non-woven protective layer.

Five, we replace the large area earthwork plastic extruded board use, greatly reduce the specific ground load, speed up the construction progress and reduce the construction cost and other advantages. Quality, and construction with the use of life XPS, can significantly improve the overall quality of the building.