- kingda XPS - flame retardant board

- kingda xps - The common blue, red, yellow

- kingda xps - Roof extrusion board

- kingda xps - Internal and external wall extrusion

- kingda xps - Cold storage and purification worksho

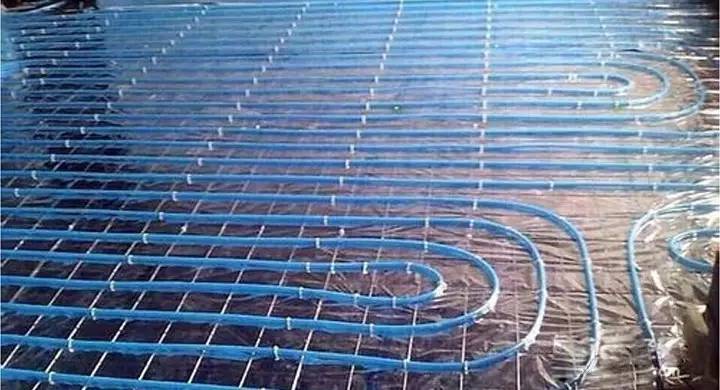

- kingda xps - Floor heating extrusion board

- kingda xps- Steel structure layer and sandwich ext

- kingda xps - Special shape sheet extrusion board

- Promotion Keywords

Dongguan city, kingda plastic insulation board co., LTD

Contact: manager zhao

Mobile phone: 13509011897

The phone: 0769-88127882

Fax:0769-88128231

Email:2875488916@qq.com

Web site:www.dgkingda.com

Address:Zhongtang town Zhancui Nan di Industrial area

-

Tools / raw materials

Boundary insulation strip, extrusion plate, mirror reflection film, clamp nail, coil pipe, heat insulating sleeve, aluminium foil glue, water purifier, raw meal belt, etc.

Art knives, rulers, brooms, nail sticking guns, measuring tape, etc.

Procedures / specifications

First, ground insulation system construction preparation:

One point one

To do ground insulation system before laying, should ensure that the ground, ground and wall have been completed, and have done the basic leveling, no other types of work in the site.

One point two

Construction room temperature should meet the requirements for reasonable use temperature of pipe material, because the environmental temperature and pipe bending radius are closely related.

One point three

Clean the ground and wall, use the horizontal ruler to proofread the flatness of the ground, within 1 meters, the difference between height and height is less than or equal to 5 millimeters. Wall or floor bulge with a shovel to fill the ground pit with concrete.

Bathrooms and villas should be prepared at the bottom of the waterproof layer or the laying of moisture-proof film.

Two, special floor heating insulation construction

Two point one

Before laying the boundary insulation bar, the wall should be cleaned to ensure the smoothness of the wall, and the insulation strip shall be removed during construction and use.

Two point two

The boundary insulation strip shall be attached to the wall and cylinder at the intersection of the ground in the heating area, and the boundary insulation strip shall have excellent adhesion fastness to ensure that it will not fall off during use.

Two point three

The boundary with insulation thickness of 8 mm, the boundary of heat preservation should have certain flexibility, ensure the backfill layer storage expansion after the buffer function, the maximum amount of compression is 5 mm. The cutting extruded plate is not allowed to replace the boundary strip.

Two point four

The boundary insulation strip shall be lapped and the length of lap shall be no less than 3 cm.

Three, the floor dedicated environmental protection Extrusion board laying

Three point one

Prior to the laying of the Extrusion board, the surface roughness of the original ground shall be guaranteed.

Three point two

Extrusion board should choose the density, compressive strength, thermal conductivity, can meet the requirements of heating technology specifications. In the conventional area, the extruded board should be made of 2 cm thickness, and the thickness of the film should be more than 2 centimeters for the environment with poor heat or poor heat insulation.

Three point three

Try to choose the extruded board specifications in order, reduce more joint.

Three point four

The connecting gap between the extrusion plate and the boundary insulation strip should be adhered together with aluminum foil tape to prevent more heat from escaping through the edge of the wall. The two pieces of extruded aluminium foil should be adhered to each other to ensure the tightness of the whole system.

Three point five

During the laying of the Extrusion board, it is necessary to avoid the wires, pipes or other pipes to cause larger cracks, and polyurethane foam treatment should be adopted.

Three point six

Extrusion board should be laid on the entire plate laying around, cutting plate laying in the middle of the principle.

Three point seven

Extrusion board laying of the gap should be no more than 5 mm, Extrusion board laying attention to the surface roughness of the plate, the difference between high and low should be less than 5 mm.

Four, floor heating dedicated reflective layer laying

Four point one

Due to the use of reflective film, the choice of reflective film should be selected alkali resistant products.

Four point two

The reflective film should be laid flat and fold as much as possible.

Four point three

Reflective film should be covered tightly, no insulation board and floor leakage.

Four point four

Reflective film laying should pay attention to square neat, easy to calculate the ground heating pipe or heating cable spacing.

Four point five

Reflective film connection should also use aluminum foil adhesive tape, avoid excessive overlap, resulting in waste of materials.

Five, the ground dedicated kart construction

Five point one

Do not use recycled materials produced by the nails, harmful to the human body.

Five point two

The material of the nail needs to meet the basic requirements of high strength and good creep performance. With the nail gun construction, the nail strength is higher, and it can bear the mechanical installation.

Five point three

The line distance card can be made every 40-50CM cards, and the bend ensures the radius of the curve. The 5 go kart shall be fixed.

Five point four

Card nail installation should pay attention to straight into the insulation layer, do not tilt the card nails, so as not to fix the effect is not good.

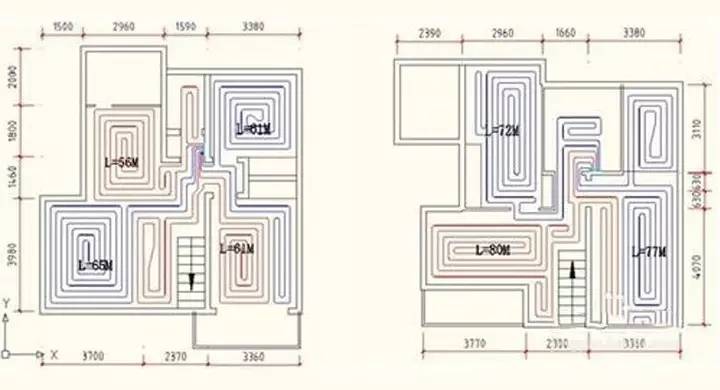

Six 、 ground pipe construction

Six point one

According to the design drawing, arrange the pipe, determine the pipe spacing and pipe direction, the straight pipe installation spacing error is less than or equal to 1cm.

Six point two

The laying of pipelines in the construction process to wear flat shoes.

Six point three

A loop should not be connected, laying, each loop length is also limited. The maximum laying length of a loop in 16x2.0mm pipe shall be less than 90m; the maximum laying length of one loop of 20x2.0mm pipe shall be less than 120m.

Six point four

In construction, excessive distortion of pipe is prohibited, and the radius of bend of pipe should be controlled less than 6 times the outer diameter of pipe.

Six point five

After the completion of the laying off, no trampling or other damage to the pipeline behavior, the ground backfill layer construction to prevent rough and brutal construction.

Seven 、 expansion joint construction

Seven point one

When the ground construction area of more than 30 square meters with more than 6 meters, should be not greater than 6 m spacing set expansion joints, each stitch setting expansion door, complex Fangxing can zoning segmentation calculation.

Seven point two

The height of the expansion joint is from the edge of the extrusion plate to the upper edge of the backfill layer, and the heating pipe at the expansion joint setting needs to be provided with a heat preservation pipe.

Seven point three

If the ground is laying marble or tile joints below the best set of tile seam.

Eight, floor heating special raw meal belt construction

Eight point one

The raw material belt should be used in the thread connection to achieve high quality sealing effect.

Eight point two

The number of winding ring of raw material belt should not be too much to prevent damage to the connecting parts.

Eight point three

The density and thickness of raw materials for heating are higher than that of the raw materials sold in the market. The raw materials should be twisted clockwise and the winding thickness of the yarn is usually from thick to thin.

Nine 、 floor heating special pipe bender and heat preservation pipe construction

Nine point one

Ground heating water diversion device has a certain height from the ground, the pipeline from the diversity of water into the ground, the general need to use the protection of the pipe bender, to play a fixed and protect the ground coil is not damaged.

Nine point two

Never use or use a metal pipe bender to cause a greater degree of damage to the pipe. Recommend a high strength plastic pipe bender.

Nine point three

The insulation pipe is used for the supply and return pipes that are exposed outside the water separator.

Nine point four

Water separator at the ground floor heating pipe is dense, in order to prevent local temperature is too high, should use insulation sleeve. Generally added to the water supply pipe, whether or not to add water, it is necessary to determine the length of the pipeline. The length of the heat insulating sleeve to the distance between the two pipes is greater than 10 centimeters.

Nine point five

Each channel shall be provided with a pipe bender, and the heat insulating sleeve is separated from it.

Ten 、 concrete backfill layer construction

Ten point one

The thickness of the backfill layer shall be the lowest and shall not be less than 5CM.

Ten point two

The proportion of Backfill Concrete shall be strictly enforced by the standards of the standard for sand, stone quality and testing methods for ordinary concrete.

Ten point three

The floor heating pipe is installed and the concrete filling layer is completed within 48 hours after the water pressure test is qualified

Ten point four

Concrete filled layer construction, prohibited the use of mechanical vibration equipment; construction personnel should wear soft shoes, the flat shovel

Ten, hanging fireplace installation

1, according to the size of the wall hanging furnace and installation before the size of the flue location, calibration accurate position, hanging furnace.

2, wall hanging furnace under the interface using hose connection.

Remarks:

The simple calculation method of power boiler as per kW with 7 square meters, such as 24 kW bigualu, can take 24*7=168 square heating area, the user's heating area of 168 square meters, can choose 24 kW bigualu bigualu, selection principle is rather large not small. Pump head hanging furnace is generally 10, so that the boiler can take up to three floor heating, heating bigualu level and elevation more than 10 meters, it must add auxiliary pump, or the use of water separator with circulating pump. Wall hanging stove with living hot water, such as users have a bathroom with 24KW wall hanging furnace, such as the user has two to three bathrooms, 28KW wall hanging furnace.

Eleven 、 concrete backfill layer construction

Ten point one

The thickness of the backfill layer shall be the lowest and shall not be less than 5CM.

Ten point two

The proportion of Backfill Concrete shall be strictly enforced by the standards of the standard for sand, stone quality and testing methods for ordinary concrete.

Ten point three

The floor heating pipe is installed and the concrete filling layer is completed within 48 hours after the water pressure test is qualified

Ten point four

Concrete filled layer construction, prohibited the use of mechanical vibration equipment; construction personnel should wear soft shoes, the flat shovel