- kingda XPS - flame retardant board

- kingda xps - The common blue, red, yellow

- kingda xps - Roof extrusion board

- kingda xps - Internal and external wall extrusion

- kingda xps - Cold storage and purification worksho

- kingda xps - Floor heating extrusion board

- kingda xps- Steel structure layer and sandwich ext

- kingda xps - Special shape sheet extrusion board

- Promotion Keywords

Dongguan city, kingda plastic insulation board co., LTD

Contact: manager zhao

Mobile phone: 13509011897

The phone: 0769-88127882

Fax:0769-88128231

Email:2875488916@qq.com

Web site:www.dgkingda.com

Address:Zhongtang town Zhancui Nan di Industrial area

-

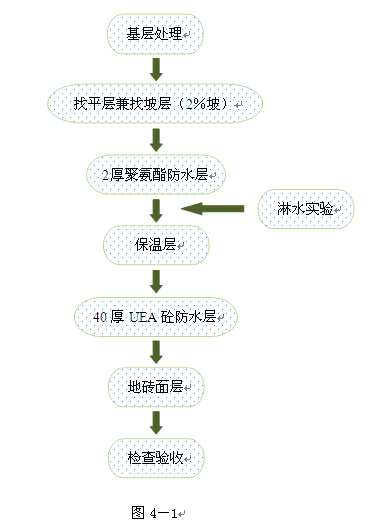

4.1 construction process

To the construction of the most flat roof 2 (with insulation) instructions: Figure 4-1

4.2, grass-roots level leveling construction

The leveling layer processing and sloping roof, but the leveling layer without adding waterproof agent, and the mixture ratio for 1:2.5 cement mortar, the thinnest 20mm, find 2% slope design drawings to the direction of. The three layer is waterproof coating, and the quality of the coating should be improved. The quality of the waterproof coating is greatly affected by the smoothness of the leveling layer, and the reliability and durability of the waterproof coating are reduced.

Construction of 4.3 polyurethane waterproof layer

In this project, the roof waterproof of the flat roof is made of 2 thick polyurethane waterproof coating.

4.3.1 construction process

The surface cleaning of the base layer is: spraying the base treatment agent the additional treatment of the special parts: coating waterproof coating and laying the carcass reinforcing material

4.3.2 before construction, should be familiar with drawings, master construction drawings in the construction requirements, node practices and related technical requirements. Arrange reasonable construction sequence. Technical explanation to construction team.

4.3.3 after primary treatment should be in the gutter, eaves gutter and roofing pipelines, chimney, sewing and other parts of the carcass reinforcing overlay additional layer of material, its width is 300mm.

First brush primer should be a 4.3.4 polyurethane paint before construction, base treatment of cold base oil evenly, with long handle brush evenly on the surface of the base, at room temperature after 4 hours after the start of construction.

4.3.5 coating waterproof layer should be built according to the principle of "first high, low back, first far and later". The first coating material away from the site, after the coating near drowning the same roof first coated with drainage concentrated mouth, gutter, eaves gutter, eaves and other joints, in large area coating.

4.3.6 matrix reinforcement long side lap width shall not be less than 50mm, short side lap width shall not be less than 70mm.

When 4.3.7 roofing coating is brushed, do not trample the layer that has not solidified, plastering waterproof ability, and easy slideway causes safety accident.

4.3.8 strictly control waterproof coating thickness, according to the design requirements of 2 thick, its inspection thickness should not be less than 80% of the design thickness.

4.3.9 in the coating waterproof layer before wet, not other construction work, coating waterproof layer shall not directly pile up things.

4.3.10 coating waterproof after completion, should be after rain or water, and after the apparent quality inspection, qualified, in order to carry out the next process construction.

4.4 insulation layer construction

The insulation layer shall be paved with a dry roof, and the insulation board shall be close to the base surface to pave and stabilize. The joints shall be filled with the same material. The quality requirements will be checked and released on the same slope roof, but no steel mesh shall be installed

4.5 concrete waterproof layer

The heat insulation layer is poured into 40 layers of C30 UEA shrinkage compensating concrete waterproof layer, and the interior of the utility model is provided with 6 steel bars and a two-way middle distance of 150. The concrete is made of ready mixed concrete. In the construction of concrete shrinkage compensation, in addition to pay attention to ordinary concrete construction precautions, we should also pay attention to the following points:

4.5.1 the concrete shall be fully wetted before placing the concrete.

Not because of 4.5.2 shrinkage compensating concrete bleeding, prone to early plastic shrinkage cracks, therefore, must pay attention to early maintenance.

4.5.3 if concrete delays time during transit, slump loss causes construction difficulties, but does not allow the addition of mixing water to avoid greatly reducing strength and expansion rate. In order to ensure proper and proper amount of retarder.

4.5.4 consider the construction of the roof, it is summer and Autumn Festival, may have high temperature or heavy rain, it is stipulated that when the temperature is more than 35 degrees, unfavorable construction, such as construction, must take cooling measures.

It is very important for 4.5.5 to compensate the shrinkage of concrete after its pouring. Immediately after pouring, the maintenance time shall be no less than 7d. Water storage and maintenance, water treatment and maintenance can be adopted.

The setting time of 4.5.6 shrinkage compensating concrete short precausions, light pressure time should be carried out in advance, should not be too late.

4.6 floor tile construction

The surface brick adopts 8~10 thick tiles, 25 thick 1:4 dry cement mortar, and the surface is sprinkled with cement. Precautions for paving bricks:

4.6.1 the grass should be cleaned and the drinks moist.

4.6.2 before paving, deal with the brick size, appearance, quality, color and other pre election, and soaked in wet, dry stand-by.

4.6.3 shop should use dry cement mortar, brick should be close and solid, mortar full, strictly control the elevation.

4.6.4 tile gap width should meet the design requirements 5 ~ 8mm.

4.6.5 tile shop sticks should wipe seam, pointing and pressing work in 24h. The depth of the crack should be brick 1/3; seamed and pointing should be using the same species, the same grade, the same number of cement, as do as clean cement, and conservation and protection.