- kingda XPS - flame retardant board

- kingda xps - The common blue, red, yellow

- kingda xps - Roof extrusion board

- kingda xps - Internal and external wall extrusion

- kingda xps - Cold storage and purification worksho

- kingda xps - Floor heating extrusion board

- kingda xps- Steel structure layer and sandwich ext

- kingda xps - Special shape sheet extrusion board

- Promotion Keywords

Dongguan city, kingda plastic insulation board co., LTD

Contact: manager zhao

Mobile phone: 13509011897

The phone: 0769-88127882

Fax:0769-88128231

Email:2875488916@qq.com

Web site:www.dgkingda.com

Address:Zhongtang town Zhancui Nan di Industrial area

-

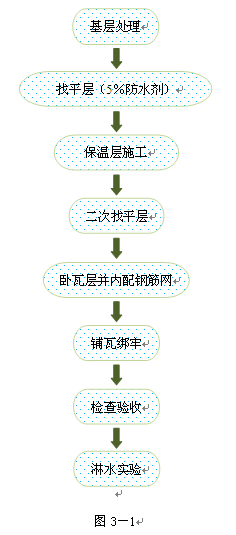

1 construction process

With a large area of use and process requirements of high slope roofing 1 (with insulation layer) instructions

2 grassroots treatment

2.1 clean mixed concrete roof residues on the surface of the dust, debris and loose concrete particles etc..

2.2 excluding the daughter wall, the wall, feet and other parts of concrete flue blocks, inclusions, and re repair.

2.3 adjust the roof reservation of the fixed 6 steel to make it straight.

3 leveling layer construction

The roof waterproof mainly adopts self waterproof, tile surface waterproof and waterproof mortar waterproof. The waterproof layer is not separately provided, and the leveling layer is doped with 5% waterproof agent as a waterproof layer. Leveling layer construction main items:

3.1 mortar layer mortar configuration, in strict accordance with the 1:3 match ratio configuration, and doped with 5% waterproof agent.

3.2, in order to prevent mortar leveling layer of mortar cracking, mixing mortar can be appropriate to add water reducing agent and micro expansion agent, and strictly control the consistency.

3.3 red bars stick ash cake: according to 1m, the thickness of plastering, roof, a range of 2 ash cake.

3.4 stay mortar slightly after closing the water, float with light pressure, before the final setting of the surface should be less on the surface does not allow, then dry cement mortar or cement slurry pressure.

3.5 after the completion of the construction of 12h, the surface should be appropriate sprinkler maintenance.

3.6 leveling layer and parapet, staircase front roof and chimneys, towers and other transfer should be left out seam, seam width is 10mm; the other is the leveling layer should also leave seam width of 10mm lattice spacing is less than or equal to 6000mm.

3.7 in case of parapet, side wall, chimney, wall wall wall along the stairs should be over 300mm.

3.8 leveling layer after hardening out strips and clean, remove the surface dust, sand, oil, mud used wire brush joint removal, and clean. Fill in compartments with asphalt ointment and prohibit construction in rain and snow.

3.9, the filling has been completed in the construction of sealing materials, protection time is generally 2 ~ 3H, in the construction of insulation layer must be protected, prohibit the occurrence of plastic deformation stampede, loss of water capacity.

3.10 detailed treatment, see roofing waterproof construction.

3.11 quality inspection standards in table 3-1

|

Serial number |

project |

Allowable deviation(mm) |

Inspection method |

|

| 中级 | 高级 |

|

||

| 1 |

Vertical elevation |

5 | 3 |

2m brace and foot examination |

| 2 |

Surface leveling |

4 | 2 |

2 feet and wedges |

| 3 |

Vertical of yin and Yang angles |

4 | 2 |

2m supporting board inspection |

| 4 |

Yin and Yang corner founder |

4 | 2 |

20cm feet and wedges |

| 5 |

Square seam straight |

3 | - |

Pull the 5m, the little wires and the ruler |

4 insulation layer construction

4.1 roofing heat insulation material selects 40mm thick extruded polystyrene board, selects the specification for 1200mm * 600mm * 40mm.

4.2, in the insulation layer before construction, should be based on the characteristics of each Huxing roof design, arrangement of roof arrangement method, arrangement order, in order to reduce the seam, to achieve the best insulation effect and material saving.

4.3 first, clean up all the rubbish and sundries in the leveling layer, and keep the surface clean, smooth and dry.

4.4, mixing special adhesive mortar, weight ratio is water: mortar =1:5, side with water edge mixing; mixing time is not less than 5min, stirring must be fully and evenly, consistency is moderate, and has a certain viscosity. After the mortar has been modulated, the 5min should be placed in static state and stirred again before use, and the mixture of mortar should be used in 1h.

4.5 deck special interface for a front brush agent improve the bonding strength and bonding mortar plastic extruded board, plastic extruded board in the thin paste surface is painted with a dedicated interface agent; interface agent to dry before applying polymer bonding mortar paste roofing construction.

Advance on the roof with black grid layout first pop-up 4.6 paste extruded board should ensure the efficiency of construction, an accurate.

4.7, the insulation board should not be broken, missing edges, off the corner, laying in case of missing edges, out of angle, broken, should be sawing, leveling, splicing use.

4.8 paste extruded plate, slab should be compact, the adjacent plate should be flush, construction control plate gap should not be more than 2mm, plate height shall not exceed 1.5mm. When the plate gap is larger than 2mm, shall be extruded strip joints with lath, not with mortar or cement bond; plate roughness height difference is greater than the location of 1.5mm should be in the construction surface before rasps, coarse paper or flat grinding wheel.

4.9, this section details specific energy-saving insulation construction program.

Standard for quality inspection of surface insulation layer

| project | Serial number |

project |

Allowable deviation(mm) |

Inspection method |

|

|

Master project |

1 |

Material quality |

design requirement |

Find out factory certificate, quality inspection report and spot sampling re Report |

|

| 2 |

Moisture content of insulating layer |

design requirement |

Check spot sampling inspection report |

||

|

Project like |

1 |

Insulation layer laying |

B50207-2002

Clause 4.2.10

|

Observation |

|

| 2 |

Inverted roof protective coating |

GB50207-2002

Clause 4.2.12

|

Needle insertion and foot measurement |

||

| 3 |

Thickness of insulating layer

Allowable deviation |

plate |

+10%,-5%

not for the time being>4mm

|

The quality of the material was calculated by observation, examination, and bulk density |

|

5, two leveling layer

The leveling layer is basically the same as the leveling layer of the base layer and the 1:3 cement mortar with a thickness of 20mm does not need to be added with waterproof agent. It should be noted that the construction of the layer should pay special attention to the protection of the finished product of the insulation layer, and avoid damage to the construction tools, materials, people, metal articles and so on.

6 layer tile construction

The horizontal tile layer is mortar layer, according to the size of tile and the arrangement of roofing tile, the thinnest place is 20mm, and the weight ratio is 1:3.

Horizontal tile mortar configuration o 6@500 * 500 steel mesh, steel mesh should be riding and straight ridge and ridge eaves embedded the 10 tie bar.

The position of the steel mesh shall be determined according to the size of the tile.

7 paving tile construction

7.1 should first check the flat tile, tile cutting edge should be neat, clear, uniform thickness, no delamination, cracks, defects such as sand and dew,

7.2 according to the arrangement of the ridge line and Bois design released the cornice line, ditch line, according to the actual size and characteristics of roof tile roof by the calculation, the actual amount of roofing tiles required that each row and pop-up tiles and each tile line position, convenient for laying tiles.

7.3 roof tiles, tile tile hanging mouth sequence is from the eaves from bottom to up and from the left to the right direction. 50 ~ 70mm pick eaves cornice.

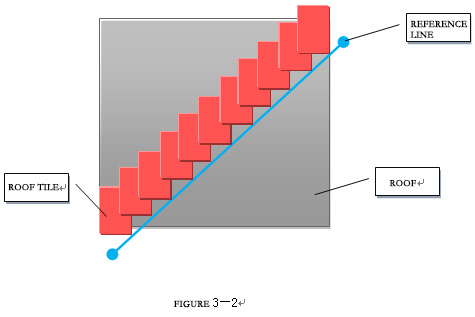

7.4 in order to ensure the smooth tiles from the roof straight, pull a slash to the eaves, the roof of the first diagonal alignment in the lower right corner of the Wah Chang, and the second row, third row second Zhang wa third, until the lower right corner of the eaves tile, are in a line. Then, from bottom to top, one by one, you can dig ditches straight, tidy and beautiful. Figure 3-2

7.5, hanging watt hour, pay attention to tile surface, corrugated straight, do not meet the quality requirements of tile can not be used.

The 7.6 oblique ridge, valley tile to tile hanging on the edge for a waterproof cover, groove width not less than 150mm, pop up line, ID number, the tile surface excess cut off or sawed off, according to the order number up.

7.7 hanging flat ridge, oblique ridge watts, should pull long thread, hanging straight paved. Buckle tile with 1:2.5 lime mortar paving block level, the gap between the tile and tile interface, with mixed crack fiber mortar block tile and tile lap Yan scraping, each side is not less than 40mm.

The joint 7.8 oblique ridge mouth down, at the junction of flat ridge and oblique ridge to use the knife grey seal. The paved ridges and ridges are straight and free of undulations.

7.9 per piece laying roof tile with double stranded wire will be No. 16 and 6 watt mesh reinforcement lashing.

Cover size and inspection method for 7.10 watt roof are shown in table 3-3

| Beijing | project |

Cover size |

Inspection method |

| 1 |

In the two tile on the roof covered slope width |

≥40 |

Ruler test |

| 2 |

Tile into the gutter, eaves gutter length |

50~70 |

|

| 3 |

Gutter, Xiegou, waterproof valley into the length of varnay |

≥150 |

|

| 4 |

Watou pick barge length |

50~70 |

|

| 5 |

The side wall tile or the chimney into the top roof flashing width |

≥50 |

The quality inspection items, requirements and inspection methods of 7.11 watt roofing project are shown in table 3-4

|

Inspection item |

Requirement |

Inspection method |

|

|

Master project |

The 1 quality of tile and tile. |

Must comply with design requirements |

Observation, inspection and inspection of factory quality certificate or quality inspection report |

|

The 2. kind of fixed |

It must be securely laid. Measures should be taken to strengthen the seismic fortification area or the roof with a slope greater than 50% |

Observation and hand wrench examination |

|

|

General project |

1. quality of hanging tiles |

Uniform distribution, flat and firm nails |

Observation |

|

2. watt surface quality |

Tile surface smooth, neat ranks. Lap closely, straight cornice |

Observation |

|

| 3. ridge |

Should be covered properly, evenly spaced, sealed tight |

Observation |

|

|

4. ridge and ridge |

Should be straight, no ups and downs |

Observation or hand examination |

|

|

5. flashing practices |

Should comply with the design requirements, straight, neat, solid, tight, no leakage |

Observe, check and check after rain or water | |

After the roofing tile has been paved, the supervision and acceptance by Party A shall first be carried out, and the water spraying test can be carried out before and after acceptance.

The water drenching test is to check whether the roof has seepage or not, and whether or not the drainage is unobstructed. The inspection should be carried out after rain or after continuous watering of 2h. After inspection, the quality acceptance records of the sub project and the water logging records shall be completed